Direct-Printed Aligners: A Clinical Status Report

As three-dimensional printing has become more widely available in private-office settings, interest in 3D-printed aligners has rapidly increased. Research groups, scientists, and companies have recently been moving away from vacuum-forming processes, instead investigating new materials for 3D-printing of aligner shells.1-3 Among these materials, Graphy’s Tera Harz TC-85,* which was approved in 2022 by the U.S. Food and Drug Administration, the European Union (CE marking), and other official bodies, has gained routine use in offices worldwide.4-7

This article outlines the clinical uses and material properties of aligners fabricated from TC-85 resin, and it presents a workflow for designing and manufacturing them in the orthodontic office.

Clinical Uses

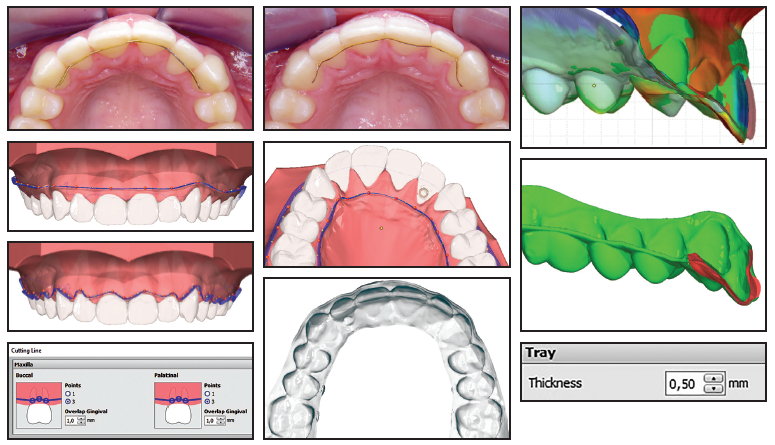

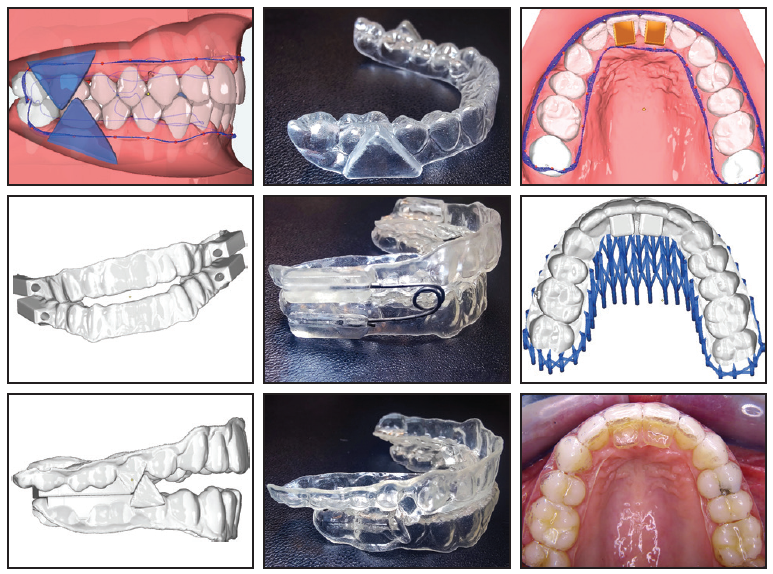

The unlimited design possibilities of 3D-printed aligners offer a significant advantage to clinicians (Fig. 1). Biomechanics can be fine-tuned not only by incorporating cutouts or bite ramps (Fig. 2), but also by adjusting the thickness of the plastic at any part of the aligner, which enables precise force delivery and the production of countermoments for root movement. Class II advancement wings can be added; a design similar to a Twin Block appliance is also possible. For retention in anterior open-bite cases or to close gaps after relapse, a tube can be incorporated for insertion of a TMA** spring. Hooks for elastics can be integrated, and trim lines can be customized.8 For extrusion, pressure columns can be used in place of attachments.9

Tera Harz TC-85 further expands the potential uses of direct-printed aligners. The material’s most prominent feature is its shape memory: after exposure to high temperatures, the aligner can be deformed to easily snap over undercuts. When the aligner is kept in an oral environment (more than 30°C) for at least 22 hours a day, as typically prescribed, any deformation required for insertion or removal will self-correct.10

Fig. 1 Altering trimlines, individualizing thickness, and adding pressure points can optimize three-dimensional movements, as demonstrated in replacement case.

Fig. 2 Digital design, fabrication, and clinical use of 3D-printed aligners, demonstrating possibilities such as advancement wings, 3D-printed tubes for manually inserted TMA** springs, and bite ramps.

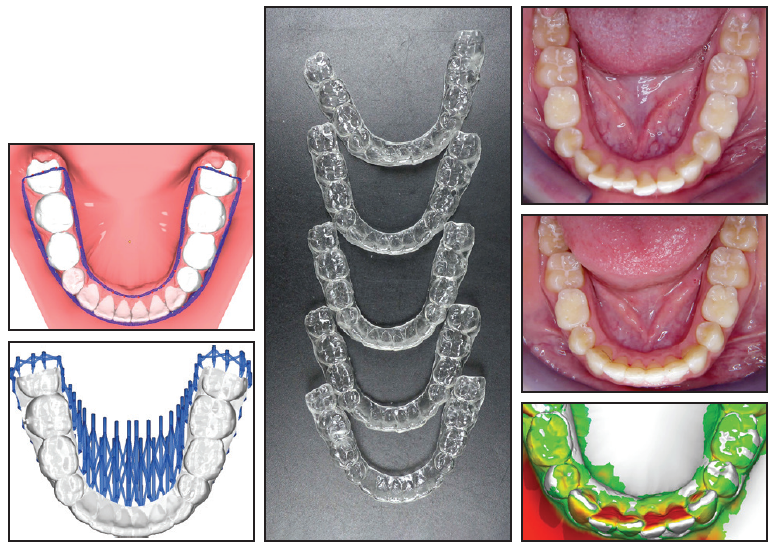

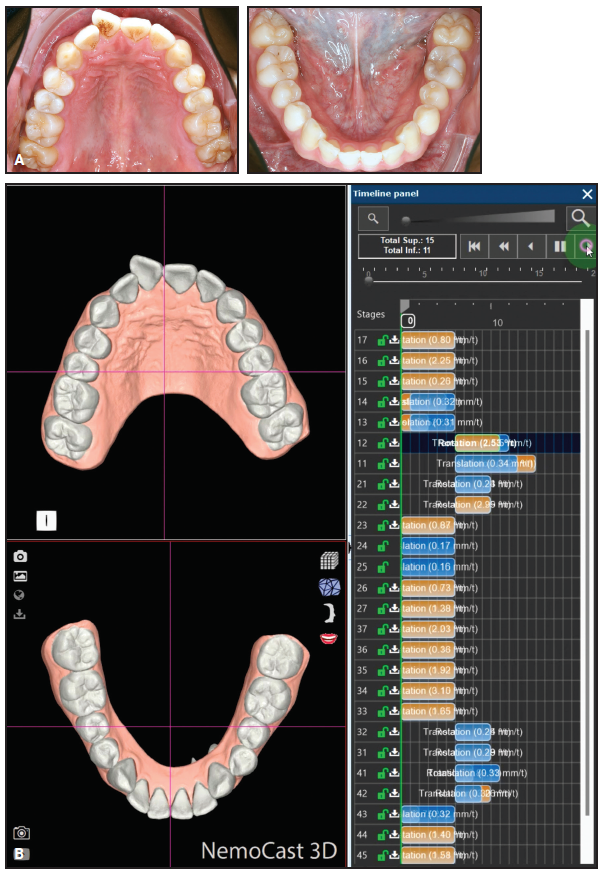

Studies have demonstrated that 3D-printed aligners can successfully treat mild crowding, with an accuracy that compares favorably to that of conventional aligners.11,12 When used in conjunction with interproximal reduction, direct-printed aligners can also predictably and effectively correct moderate crowding (Fig. 3). Furthermore, their customizability makes these aligners ideal for unexpected complications or support during the finishing stages of difficult cases.13

Fig. 3 3D-printed aligners used in combination with interproximal reduction for treatment of moderate crowding.

Material Properties

Force Delivery

Several studies have measured the forces exerted by direct-printed aligners. Customizing the thickness at different parts of the aligner tray has been found to better distribute the applied forces, thereby reducing side effects.14,15 The flexibility and viscoelastic properties of TC-85, in particular, enable the aligners to apply continuous, light forces; in one study, the force levels produced by direct-printed aligners during extrusion were found to be significantly lower than those of thermoformed aligners.9 Moreover, as Lee and colleagues reported, the material’s shape memory and, hence, geometric stability at high temperatures appear to reduce the amount of force decay caused by repeated insertion and removal.10 In a contrasting study, however, Sayahpour and colleagues found greater rigidity and more force decay with 3D-printed aligners than with vacuum-formed aligners.16

Wear and Aging

Tera Harz TC-85 is a urethane dimethacrylate-based photopolymer. At room temperature, aligners printed with TC-85DAC, the clear variant of this resin, are transparent and stiff, much like conventional thermoformed aligners. Photocurable resins such as TC-85D form 3D networks through radical polymerization, allowing them to revert to their original shapes after deformation, even if they are heated above the glass transition temperature. Therefore, unlike typical thermoplastic aligners, TC-85 aligners can remain at body temperature without losing force from deformation.

In fact, a study showed that aligners printed from TC-85 resin kept their mechanical properties for at least one week of intraoral use.17 After a week of wear, however, surface roughness and porosity were found to increase,18,19 potentially leading to more bacterial adhesion and biofilm formation in comparison with Invisalign*** aligners.

In addition to mechanical wear, chemical aging of direct-printed aligners has been investigated. No cytotoxic chemicals or estrogen mimics were detected after aligners fabricated with TC-85 were aged in water for two weeks.20 In another study, no leaching of bisphenol A was detected, but the material was found to release urethane dimethacrylate.21 The significant variability among samples suggested potential inconsistencies in the fabrication process.21 To avoid this issue, strict protocols for aligner manufacturing should be followed.

Accuracy

Park and colleagues recently evaluated variations in aligner thickness caused by manufacturing differences, using micro-computed tomography and spectrophotometry to measure the gap width of thermoformed and 3D-printed aligners.22 While changes in thickness were found in all aligners after printing and post-production—the thickness of 3D-printed aligners tended to increase and that of thermoformed aligners to decrease—the direct-printed aligners exhibited smaller gap widths, indicating a better fit.22 Corroborating these results, Koenig and colleagues found that the trueness and precision of direct-printed aligners were superior to those of thermoformed aligners.23

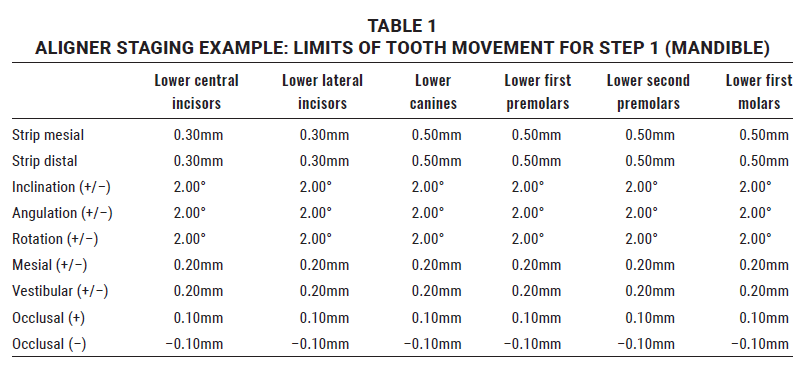

Manufacturing Process

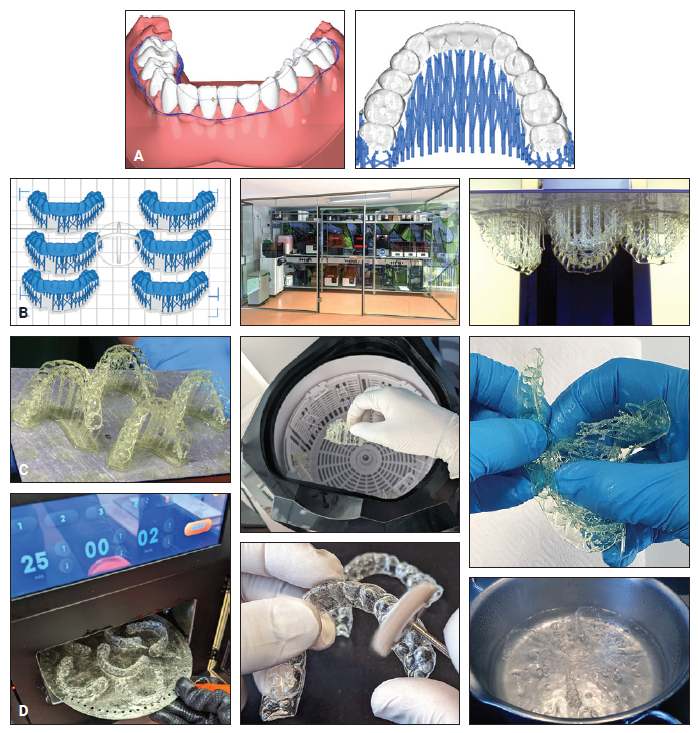

Production of 3D-printed aligners involves four basic steps (Fig. 4). First, the digital setup and staging are performed (Table 1). Next, the aligner shells are adjusted using either a dedicated slicer program such as Chitubox† or the slicing capabilities of the design software, then fabricated with certified 3D printers. The printed aligners are cleaned in an alcohol-free process by spinning them in a dedicated centrifuge, and the supports are manually removed. Finally, the aligners are light-cured and ultrasonically cleaned. A detailed workflow is presented below.

Fig. 4 Four major steps required for direct printing of aligners. A. Digital setup (left), staging (Table 1), and automatic generation of support structures (right). B. Aligner shells adjusted on virtual printing platform in slicer software (left) and printed on certified printers (center, right). C. Printed aligners (left) centrifuged (center), then supports removed by hand (right). D. Aligners light-cured in nitrogen atmosphere (left), followed by polishing (center) and ultrasonic cleaning (right).

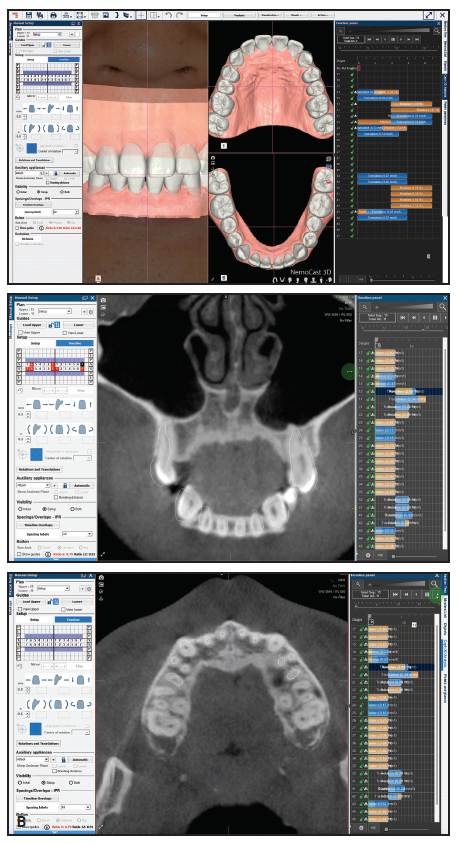

Software

The digital setup can be done with a variety of software platforms, including paid options such as NemoStudio,‡ Onyxceph,†† Deltaface,‡‡ 3Shape,§ Blue Sky Plan,§§ uLab,§§§ ArchForm,**** and Maestro 3D.§§§§ In addition, Graphy has released Direct Aligner Designer* (DAD), a free-to-use software platform that combines treatment planning with aligner design. Key features of this program include options for altering aligner thickness, customizing aligner margins for improved force delivery and retention, and adjusting resolution to enable the use of additional orthodontic devices with complex geometries. Aligners can also be engraved with patient names or tray numbers. The program includes an automatic block-out feature that fills in small gaps to ensure successful one-piece printing.

Once the shells are designed, the software automatically attaches supports for printing the aligners, significantly enhancing workflow efficiency and operational ease (Fig. 4A). (If a design platform without slicing capabilities is used, the aligner shells can be saved as STL files and imported into a program such as Chitubox, which will generate support structures.)

Printing and Post-Processing

With many 3D printers, six to eight aligners can be fabricated simultaneously over the course of 30-60 minutes (Fig. 4B). Because the materials are not immediately sturdy or biocompatible after printing, several post-processing stages are required, as with conventional aligner production. First, the aligners are centrifuged to remove residual resin, which takes about six minutes; many centrifuges can accommodate as many as eight aligners at once (Fig. 4C). Next, the support structures are removed either by hand or with nippers, which takes about a minute per aligner. The trays are then given an ultraviolet light-cure in a nitrogen atmosphere; Graphy’s Tera Harz Cure* nitrogen generator will completely cure six to eight aligners in 17-25 minutes (Fig. 4D). Any remaining support parts are trimmed, and the aligners are polished, a process that takes only one or two minutes. Finally, the trays are washed in an ultrasonic bath of room-temperature water for two minutes, dried for 10 minutes, washed again in 100°C water for another minute, and dried for another 10 minutes (a total of about 25 minutes).

Effects of the Manufacturing Process

The particular 3D printers and post-production processes that are used may affect the mechanical properties of direct-printed aligners and, consequently, their clinical performance.24 The mechanical properties of the trays do not appear to be altered by post-curing in a nitrogen atmosphere,25 heat treatment,25 or directional printing.26 While ultraviolet-light-curing is crucial to ensure rigidity, an extended curing time has little effect on accuracy.27

The tendency of direct-printed aligners to increase in thickness after the manufacturing process may negatively affect their clinical utility.22,28 No direct associations have been found between curing time or nitrogen-generator use and aligner thickness, but trays printed at a 60° inclination and then centrifuged did exhibit a local increase in thickness at the anterior teeth.29

Conclusion

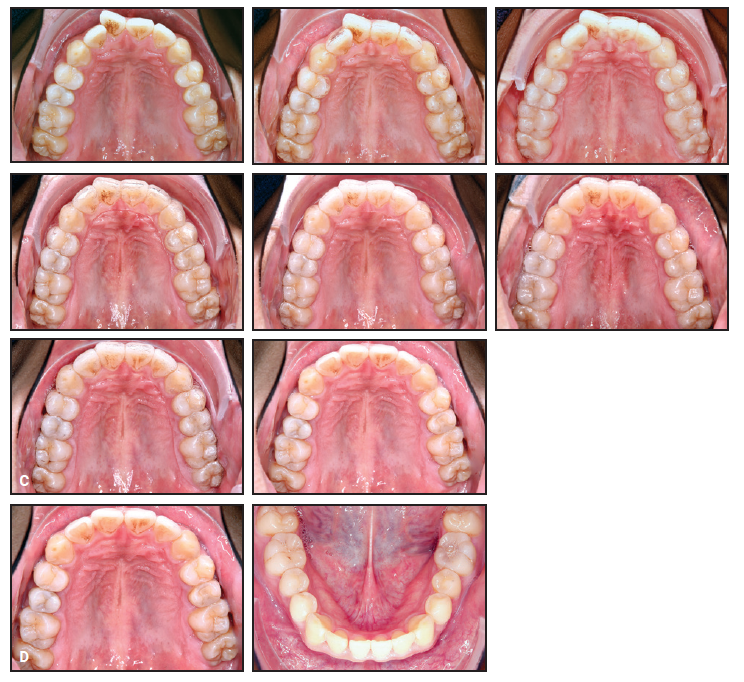

Direct-printed aligners provide orthodontists with enough flexibility to maintain full control over the treatment workflow ([img=5A]Fig. 5A, 5B and 5C).

Fig. 5 Sample case treated with combination of enamel reduction, slight expansion, and uprighting. A. Patient with Class I relationship and anterior crowding before treatment. B. Planning and staging performed in NemoStudio‡ software (continued in next image).

Fig. 5 (cont.) Sample case treated with combination of enamel reduction, slight expansion, and uprighting. B. Planning and staging performed in NemoStudio‡ software (continued in next image).

Fig. 5 (cont.) Sample case treated with combination of enamel reduction, slight expansion, and uprighting. C. Progress of treatment with 17 sets of aligners. D. Final results after four months of treatment.

As evidence of clinical efficacy continues to emerge, in-house aligner fabrication will become increasingly widespread. Nevertheless, practitioners must carefully evaluate their aligner manufacturing processes and materials to ensure they can continue providing low-risk, effective treatment.

FOOTNOTES

- *Trademark of Graphy, Inc., Seoul, South Korea; www.itgraphy.com.

- **Registered trademark of Ormco Corporation, Brea, CA; www.ormco.com.

- ***Registered trademark of Align Technology, Inc., San Jose, CA; www.aligntech.com.

- †Chitu Systems, Commerce, CA; www.chitubox.com.

- ‡Registered trademark of Nemotec, Madrid, Spain; nemostudio.nemotec.com.

- ††Registered trademark of Image Instruments, Chemnitz, Germany; www.onyxceph.eu.

- ‡‡Registered trademark of Deltaface, Limoges, France; www.deltaface.com.

- §Registered trademark of 3Shape, Copenhagen, Denmark; www.3shape.com.

- §§Registered trademark of Blue Sky Bio, Libertyville, IL; www.blueskyplan.com.

- §§§ULab Systems, Memphis, TN; www.ulabsystems.com.

- ****ArchForm, Sunnyvale, CA; www.archform.com.

- §§§§AGE Solutions, Pontedera, Italy; www.maestro3d.com.

REFERENCES

- 1. Tartaglia, G.M.; Mapelli, A.; Maspero, C.; Santaniello, T.; Serafin, M.; Farronato, M.; and Caprioglio, A.: Direct 3D printing of clear orthodontic aligners: Current state and future possibilities, Mater. (Basel) 14:1799, 2021.

- 2. Maspero, C. and Tartaglia, G.M.: 3D printing of clear orthodontic aligners: Where we are and where we are going, Mater. (Basel) 13:5204, 2020.

- 3. Nakano, H.; Kato, R.; Kakami, C.; Okamoto, H.; Mamada, K.; and Maki, K.: Development of biocompatible resins for 3D printing of direct aligners, J. Photopolymer Sci. Technol. 32:209-216, 2019.

- 4. Panayi, N.C.: Directly printed aligner: Aligning with the future, Turk. J. Orthod. 36:62-69, 2023.

- 5. Schupp, W.; Haubrich, J.; Klingberg, M.; Boisserée, W.; Sim, U.S.; and Kim, H.: Shape memory aligners: A new dimension in aligner orthodontics, J. Align. Orthod. 7:113-127, 2023.

- 6. Kim, K.B. and Graf, S.: Direct printing of clear aligners, J. Clin. Orthod. 57:450-458, 2023.

- 7. Bichu, Y.M.; Alwafi, A.; Liu, X.; Andrews, J.; Ludwig, B.; Bichu, A.Y; and Zou, B.: Advances in orthodontic clear aligner materials, Bioact. Mater. 22:384-403, 2023.

- 8. Panayi, N.; Cha, J.Y.; and Kim, K.B.: 3D printed aligners: Material science, workflow and clinical applications, Sem. Orthod. 29:25-33, 2023.

- 9. Thai, L.H.: Comparison of force levels between thermoformed and direct printed aligners during extrusion and rotation of a maxillary central incisor, thesis, St. Louis University, St. Louis, 2022.

- 10. Lee, S.Y.; Kim, H.; Kim, H.J.; Chung, C.J.; Choi, Y.J.; Kim, S.J.; and Cha, J.Y.: Thermo-mechanical properties of 3D printed photocurable shape memory resin for clear aligners, Sci. Rep. 12:6246, 2022.

- 11. Hertan, E.; McCray, J.; Bankhead, B.; and Kim, K.B.:. Force profile assessment of direct-printed aligners versus thermoformed aligners and the effects of non-engaged surface patterns, Prog. Orthod. 23:49, 2022.

- 12. Knode, V.; Ludwig, B.; Retrouvey, J.M.; Pandis, N.; Schmid, J.Q.; Erbe, C.; and Fleming, P.S.: Directly printed aligner therapy: A 12-month evaluation of application and effectiveness, Am. J. Orthod., in press.

- 13. Migliorati, M.; Drago, S.; Castroflorio, T.; Pesce, P.; Battista, G.; Campobasso, A.; Gastaldi, G.; Valvecchi, F.F.; and De Mari, A.: Accuracy of orthodontic movements with 3D printed aligners: A prospective observational pilot study, Kor. J. Orthod. 54:160-170, 2024.

- 14. Grant, J.; Foley, P.; Bankhead, B.; Miranda, G.; Adel, S.M.; and Kim, K.B.: Forces and moments generated by 3D direct printed clear aligners of varying labial and lingual thicknesses during lingual movement of maxillary central incisor: An in vitro study, Prog. Orthod. 24:23, 2023.

- 15. Remley, M.L.; Kim, K.B.; Carvalho Miranda, G.F.P.; Bankhead, B.; McCray, J.; and Kim, K.B.: Force assessment of thermoformed and direct-printed aligners in a lingual bodily movement of a central incisor over time: A 14-day in vitro study, J. Kor. Dent. Sci. 16:23-34, 2023.

- 16. Sayahpour, B.; Zinelis, S.; Polychronis, G.; Eliades, T.; Goteni, M.; Kopp, S.; and Eslami, S.: Effects of intraoral aging on mechanical properties of directly printed aligners vs. thermoformed aligners: An in vivo prospective investigation, Eur. J. Orthod. 46:cjad063, 2024.

- 17. Can, E.; Panayi, N.; Polychronis, G.; Papageorgiou, S.N.; Zinelis, S.; Eliades, G.; and Eliades, T.: In-house 3D-printed aligners: Effect of in vivo ageing on mechanical properties, Eur. J. Orthod. 44:51-55, 2022.

- 18. Koletsi, D.; Panayi, N.; Laspos, C.; Athanasiou, A.E.; Zinelis, S.; and Eliades, T.: In vivo aging-induced surface roughness alterations of Invisalign and 3D-printed aligners, J. Orthod. 50:352-360, 2023.

- 19. Eslami, S.; Kopp, S.; Goteni, M.; Dahmer, I.; and Sayahpour, B.: Alterations in the surface roughness and porosity parameters of directly printed and Invisalign aligners after 1 week of intraoral usage: An in vivo prospective investigation, Am. J. Orthod. 165:73-79, 2024.

- 20. Pratsinis, H., Papageorgiou, S.N.; Panayi, N.; Iliadi, A.; Eliades, T.; and Kletsas, D.: Cytotoxicity and estrogenicity of a novel 3-dimensional printed orthodontic aligner, Am. J. Orthod. 162:e116-e122, 2022.

- 21. Willi, A.; Patcas, R.; Zervou, S.K.; Panayi, N.; Schätzle, M.; Eliades, G; Hiskia, A.; and Eliades, T.: Leaching from a 3D-printed aligner resin, Eur. J. Orthod. 45:244-249, 2023.

- 22. Park, S.Y.; Choi, S.H.; Yu, H.S.; Kim, S.J.; Kim, H.; Kim, K.B.; and Cha, J.Y.: Comparison of translucency, thickness, and gap width of thermoformed and 3D-printed clear aligners using micro-CT and spectrophotometer, Sci. Rep. 13:10921, 2023.

- 23. Koenig, N.; Choi, J.Y.; McCray, J.; Hayes, A.; Schneider, P.; and Kim, K.B.: Comparison of dimensional accuracy between direct-printed and thermoformed aligners, Kor. J. Orthod. 52:249-257, 2022.

- 24. Zinelis, S.; Panayi, N.; Polychronis, G.; Papageorgiou, S.N.; and Eliades, T.: Comparative analysis of mechanical properties of orthodontic aligners produced by different contemporary 3D printers, Orthod. Craniofac. Res. 25:336-341, 2022.

- 25. Mattle, M.; Zinelis, S.; Polychronis, G.; Makou, O.; Panayi, N.; Papageorgiou, S.N.; and Eliades, T.: Effect of heat treatment and nitrogen atmosphere during post-curing on mechanical properties of 3D-printed orthodontic aligners, Eur. J. Orthod. 46:cjad074, 2023.

- 26. Camenisch, L.; Polychronis, G.; Panayi, N.; Makou, O.; Papageorgiou, S.N.; Zinelis, S.; and Eliades, T.: Effect of printing orientation on mechanical properties of 3D-printed orthodontic aligners, J. Orofac. Orthop., in press.

- 27. Kanase, A.; Misra, V.; and Sobti, R.: The effect of post-ultraviolet light curing on the accuracy of direct-printed aligners: An in vitro study, Australas. Orthod. J. 40:85-94, 2024.

- 28. Edelmann, A.; English, J.D.; Chen, S.J.; and Kasper, F.K.: Analysis of the thickness of 3-dimensional-printed orthodontic aligners, Am. J. Orthod. 158:e91-e98, 2020.

- 29. Migliorati, M.; Drago, S.; Lagazzo, A.; and Campobasso, A.: Effect of curing time and nitrogen generator usage on direct 3D-printed aligners thicknesses—An in vitro micro-CT study, Appl. Sci. 13:11952, 2023.

COMMENTS

.