Welding of TMA Wire: Clinical Applications

Beta titanium (TMA) wire has been proven to be highly useful in orthodontic treatment because of its intermediate stiffness between stainless steel and the nickel titanium memory alloys. In addition, it is highly formable and has approximately twice the springback or range of action of an equivalent stainless steel wire. One of the unique characteristics of TMA is its ability to be welded without soldering, to produce effective joints that do not weaken the mechanical properties of the wire.

Stainless steel wires can be welded; unfortunately, if the weld is hot enough to produce an adequate union, degradation of properties occurs and the welded wires are softened. Light tack welds can be made with steel, but they must be reinforced by solder. Studies have shown that the welding of TMA, if properly performed, will not produce significant growth in grain size or reduction in springback or strength; in fact, the joint might be stronger than a single wire, since two wires are joined together. The purpose of this article is to discuss the clinical technique of TMA welding and clinical applications based on the versatility of such welding.

Principles of TMA Welding

Although a wide range of welder settings or heats can be used to successfully weld TMA, it is important that the wires not be overheated and, in particular, that localized heats be used. True, if the wire is overheated there is little degradation in overall strength, and the high springback will remain. Overheating, however, may produce brittleness in the wire, particularly adjacent to a welded joint; also, metal flow or cracks can form that would also weaken the wire, potentially leading to wire fracture. In order to obtain proper localized heats, five welding principles must be considered: proper positioning, minimum voltage, small contact area, a single short pulse, and pressure.

The welding procedure will be demonstrated on the Rocky Mountain Dial-a-Weld 506A. Any welder that can variably control voltage can be used. The Rocky Mountain welder has the advantage of a separate setting (No. 1 wire weld setting) in which a capacitance single pulse is discharged to the wire (Fig. 1). At the No. 1 setting, a variable rheostat with a separate dial indicator incrementally changes the voltage.

Most of the commercially available welders have limited pressure control. For that reason, pressure will be considered a constant and the other variables will be controlled for optimizing a weld. Generally speaking, the greater the pressure, the higher the required voltage.

Positioning

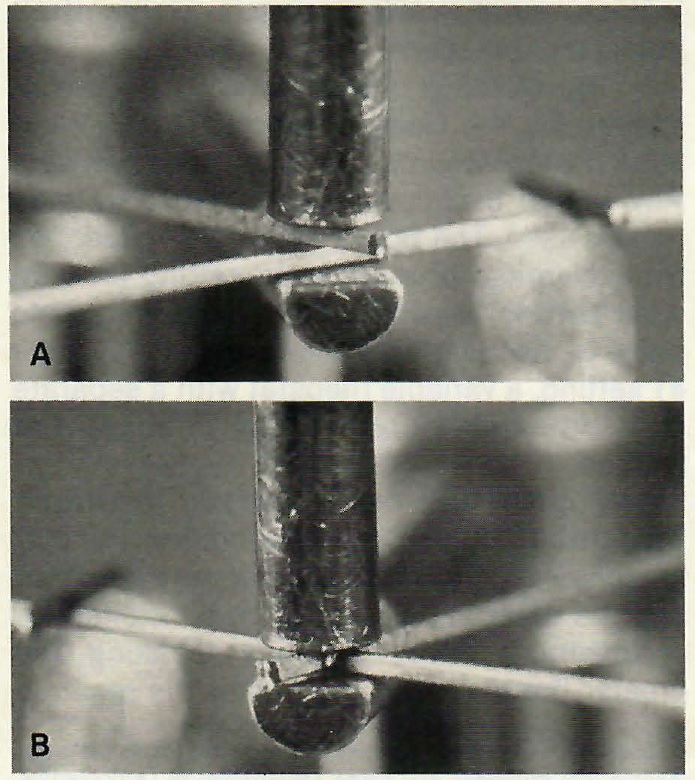

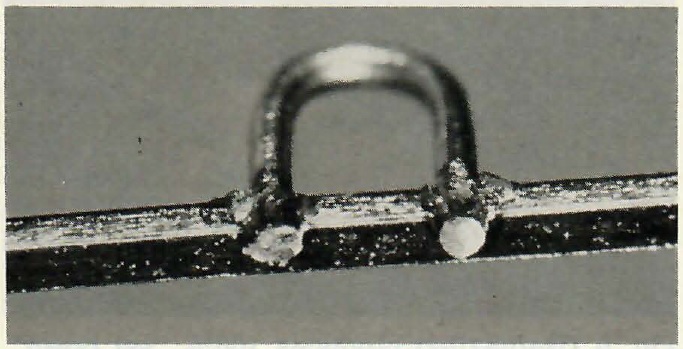

In welding two wires, it is necessary to position the wires so that they are constantly held in contact throughout the heating process. It is advantageous to use large electrodes. Note in Figure 2A that the electrodes have been turned around so that the broad, flat electrodes are used, rather than the thin, pointed electrodes. This assures that the parts are properly held together before the welding process and during heating.

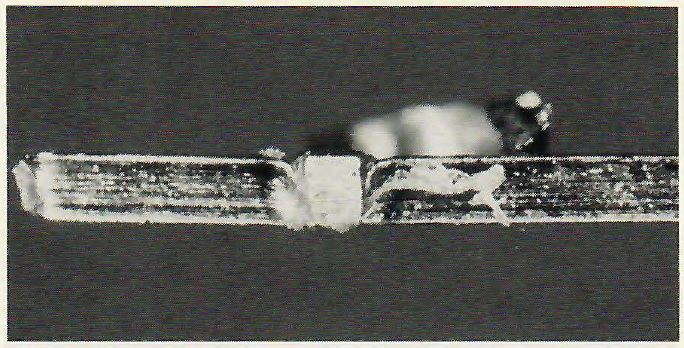

When the current is applied through the two wires, a melting process occurs (Fig. 2B). This is not just a surface weld, but an actual merging in which one wire has "set down" about 80% into the second wire. The concept of "set down" is important in evaluating the success of welds. A 25-60% "set down" is recommended for most applications.

Voltage

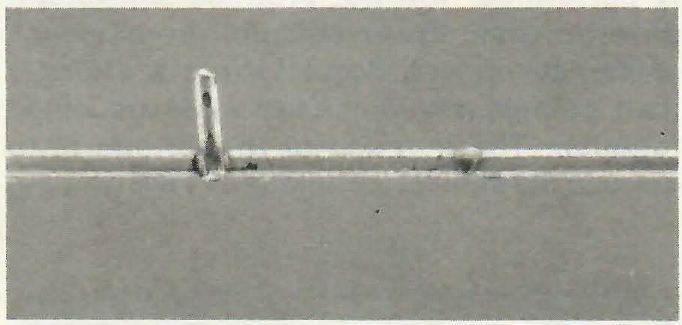

The amount of current or voltage applied is the most important variable under the control of the orthodontist. Because the welders of different companies have different properties, a simple clinical procedure can be used to determine the proper voltage. If a very low voltage is used, the welded parts will not stick together. If the voltage is gradually increased, a weld will eventually occur. The welded joint should then be tested by twisting one wire torsionally with a plier. At low voltages the welded portion will twist off, leaving a groove in the wire (Fig. 3). As the voltage is gradually increased further, a point will be reached where it is not possible to delaminate the weld joint by twisting. This would be the correct voltage setting for that size wire and joint. On the Rocky Mountain Dial-a-Weld, the correct voltage setting will lie somewhere between 6 and 10 on the No. 1 wire weld setting.

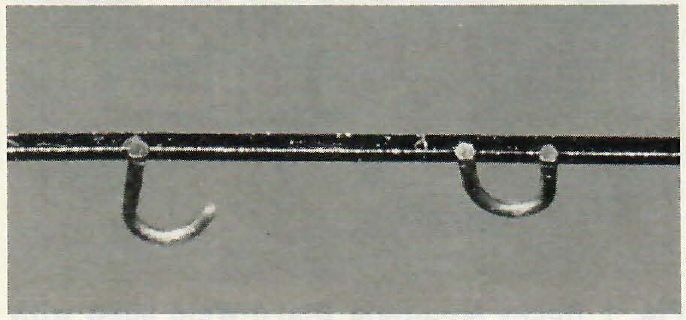

Greater voltages leading to increased heat may lead to increased wire brittleness; however, springback properties would not be affected. Even with the best joints, therefore, one should be very careful about making bends immediately adjacent to welded joints. A properly welded joint should look relatively clean, with a "set down" between 25% and 60% (Fig. 4).

Contact Area

The greater the contact area, the higher the voltage required. Smaller contact areas between parts are desirable because higher localized heats are produced, giving an excellent weld without influencing the remainder of the wire. If two round wires are welded together, only a point contact is present at the beginning of the weld; therefore, round wires are very simple to weld and require slightly lower voltages than other wires.

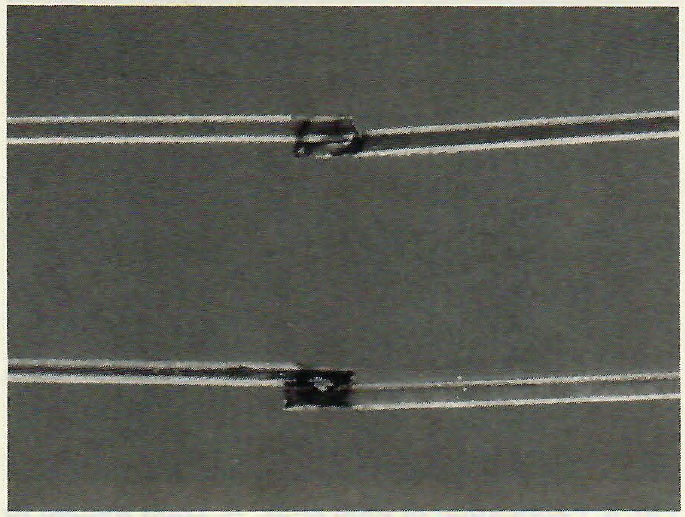

An edgewise hook welded to an edgewise wire is best welded with the smallest dimension next to the wire. Two wires can be welded longitudinally, provided the overlap of the two wires is kept small--perhaps 1mm or less--to minimize the contact area (Fig. 5). A "T" joint is preferable for most orthodontic applications because it has the smallest contact areas.

Pulse

It is important that the basic weld be accomplished with only one pulse, and that the pulse be of very short duration. If a weld is not strong enough because of low voltage, a second or third pulse is rarely successful in producing the desired weld. This can be explained by the "set down" that occurs after the initial pulse. The "set down" produces a large contact area between the two wires, and thereafter the heat is dissipated so that insufficient heat is available to the parts. If an error is made in welding and the wire twists off, one should move the weld joint to another part of the wire and then use the proper voltage. If parts are correctly welded, additional pulses may not be harmful .

Improper Welding

Improper welding can occur at the two extremes. When the voltage is too low, the parts may delaminate. When the voltage is too high, the wire can become brittle.

There are other reasons for not overheating the wires. In Figure 6 a hook has been welded, and overheating has produced a 100% "set down" in the main archwire. Notice the cracks that formed around the hook as the wire cooled. If the main archwire were bent, this could lead to fracture. This is why I recommend that the "set down" typically be no more than 60%.

Overheating can also make the wire begin to melt and flow (Fig. 7). This does not present a problem with a hook, but when an active member such as a finger spring is welded, a weakening can occur because of the reduction in the cross-section of the spring.

Clinical Applications

TMA can be welded for both passive and active use. Passive applications include stops and tieback hooks. The active applications are perhaps more exciting, because the wires can be welded without loss of springback properties.

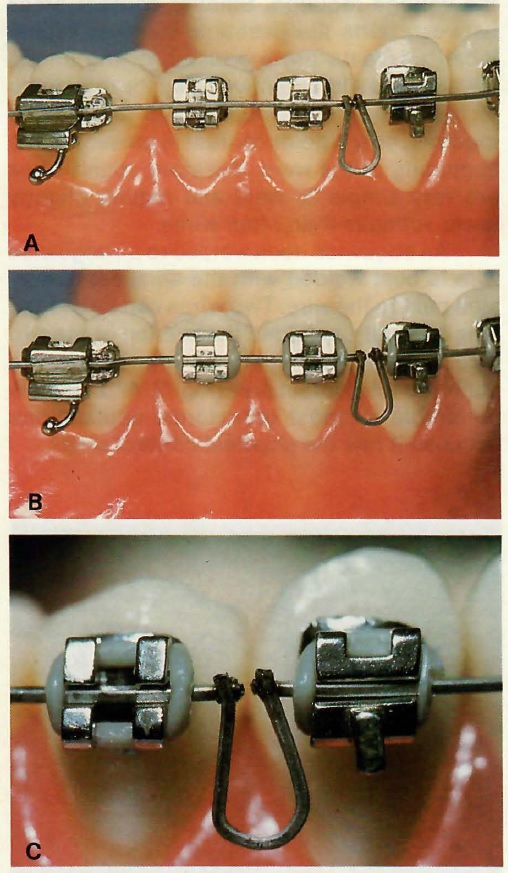

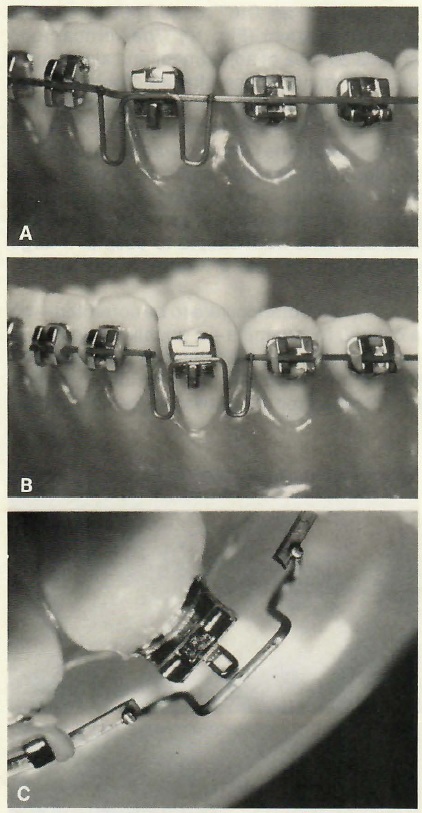

A continuous arch with vertical loops for space closure can be bent directly into a TMA wire, but it is simpler to weld the vertical loop to the continuous arch (Fig. 8). The archwire is then cut with a sharp ligature cutter to produce the vertical loop arch. Because TMA is softer than stainless steel, a ligature cutter can be safely used if the plier points are avoided.

There are a number of advantages to a welded loop arch other than convenience of fabrication. The main continuous arch can be .017" x .025" or .021" x .025" TMA, allowing greater rigidity throughout the arch and minimizing possible side effects of lighter wires. The loop should be made of .016" or .018" round TMA, reducing the amount of force produced during space closure. In addition, if space opens inadvertently during treatment, an existing archwire can be used and loops welded in place, thereby saving one from making a new wire. Following space closure the ends of the wire can be welded together with a small section, also making an additional archwire unnecessary.

To gain space in the anterior segment, vertical loops are often placed mesial to the cuspid and bent into an archwire. This can be time-consuming and requires accurate wire bending. An alternative approach would be to weld a small loop onto a continuous archwire to direct a distal force against the cuspid, advancing the wire away from the anterior teeth (Fig. 9). An .016" or .018" round wire can be used. The low stiffness of TMA may allow direct insertion of the wire into the anterior teeth, or a separate wire of even lower stiffness (such as a nickel titanium or braided wire) can be placed, with the larger round wire tied on top as an overlay until all rotations have been corrected.

At that time the round TMA wire can be placed directly into the bracket. Finally, the welded loop can be removed so that the main wire becomes a finishing arch.

In situations where the posterior teeth are well aligned but alignment discrepancies remain in the anterior segment, a composite continuous archwire can be made. An .021" x .025" TMA wire in the posterior segment is connected to an .016" round TMA wire in the anterior segment (Fig. 10). The vertical loop acts as an area of adjustment and also can be used for minor space closure. Such an archwire allows for definitive alignment and finishing of the posterior segment with the stiffer wire, while the less stiff wire simultaneously aligns the anterior teeth more efficiently. The possibility also remains for the anterior portion of the wire to act as an overlay over a less stiff wire from cuspid to cuspid, if large discrepancies are present in the incisor region.

If major rotations are to be corrected--on a cuspid, for example--a double vertical loop can be welded on both sides of the tooth and the main wire cut (Fig. 11). The loop can then be activated (or the activation can be placed before welding) to rotate the cuspid or, as in Figure 11, to move the cuspid to the buccal.

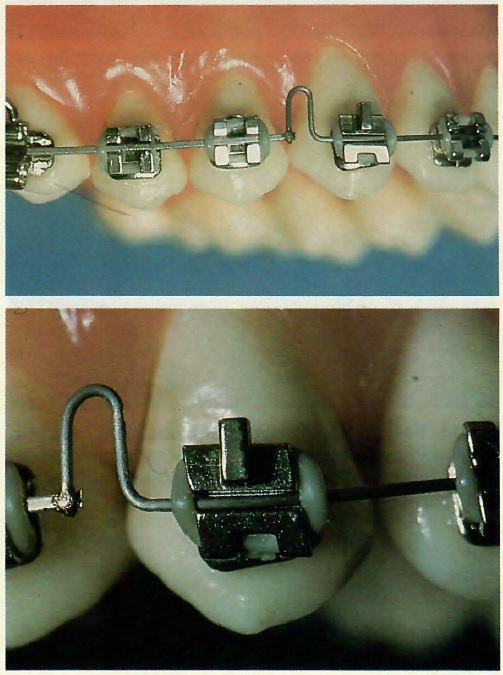

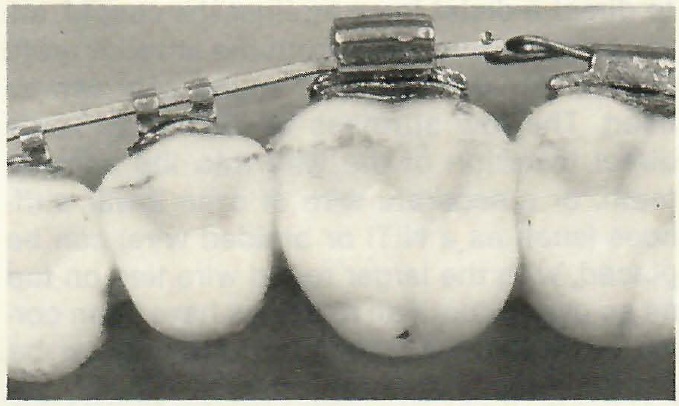

It is common for second molars not to be banded at the beginning of treatment. Later, when second molars erupt, they may be in poor buccolingual position or rotated. At that time a full archwire is usually in place. If the wire is TMA, a loop can be welded to the distal end of the archwire to align the second molar (Fig. 12). The need for a new archwire is eliminated and, more important, there are biomechanical advantages in working with a relatively rigid wire anteriorly against the second molar. A tube can be attached to the second molar, or a bracket can be attached to a malaligned molar for easier insertion of the wire. A convertible buccal tube on the first molar facilitates the placement of future archwires. If a second molar is buccally positioned and rotated with its mesial cusp toward the lingual, it is desirabie to place the larger anterior wire as far distally as possible. This produces a more consistent configuration in which efficiency is increased both for rotating the molar and for moving it lingually.

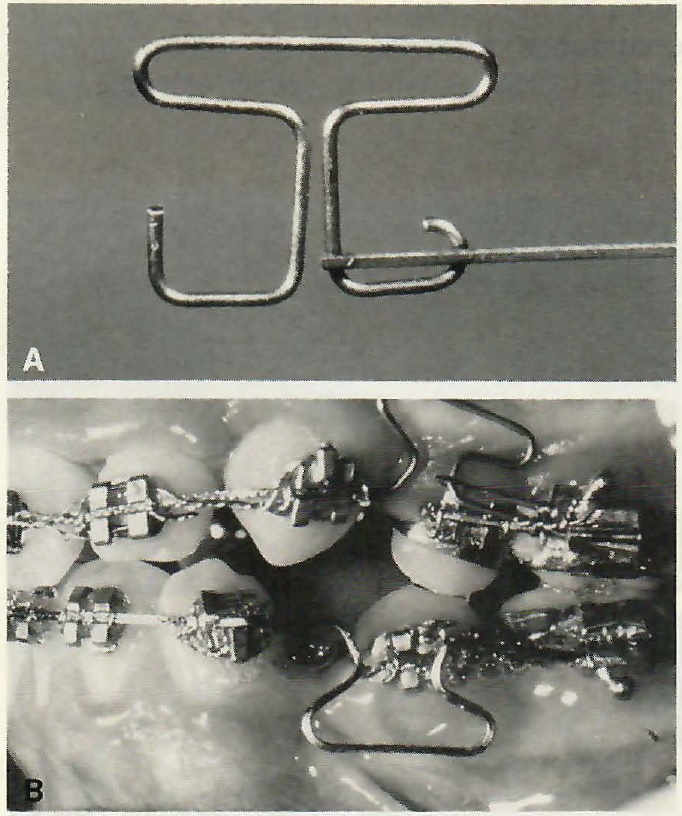

The ability to weld TMA allows for the development of more sophisticated force-driven appliances, such as the composite retraction spring used in the segmented arch technique (Fig. 13A). By joining an .018" round wire to an .017" x .025" base arch, a unique force system can be created. Controlled tooth movement occurs in the anterior segment, while a large tipback moment is present on the posterior teeth. The smaller anterior wire is used to reduce the force and make the force more constant during retraction; the larger posterior wire insures adequate tipback.

The upper arch in Figure 13B shows a composite spring used to retract the anterior teeth. Initially, a low stiffness braided wire (or other means) is used to align the six anterior teeth while retraction occurs simultaneously. At the next appointment the braided wire is removed and a stiffer wire placed so that true en masse movement of the six anterior teeth can occur. The lower arch shows a symmetrical TMA "T" spring (not welded) designed to produce reciprocal space closure between the anterior and posterior teeth.

Summary

Beta titanium (TMA) wire can be directly welded without solder, producing joints that have high springback and strength. As the only orthodontic wire with this capability, TMA offers the potential for many applications during treatment, particularly where welding is required for active tooth movement.

Although a wide range of voltages can be successfully used for welding, it is important to understand and apply the basic principles of welding: proper wire positioning, correct voltages, small contact areas, and the use of a single short pulse.