CLINICAL AID

An Economical Alginate Mixer

Mixing alginate manually requires skill and practice. No matter how experienced the operator, however, small lumps or air bubbles are commonly found in the final mixture.

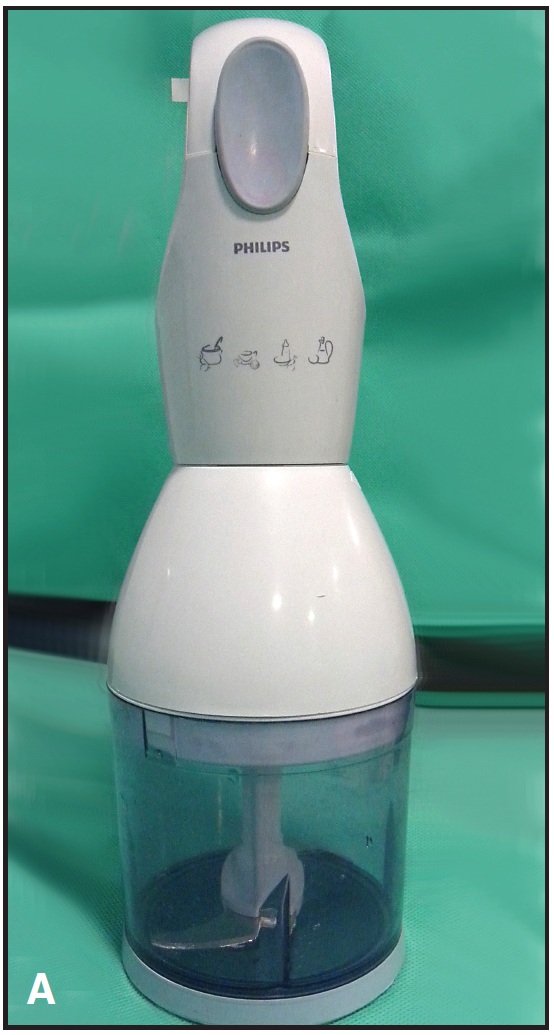

Automated alginate mixers eliminate operator skill as a factor, but are relatively expensive and hard to find in some regions. We have modified a hand-held food blender/chopper with an attachable bowl* (A) to mix alginate.

Modification and Operation

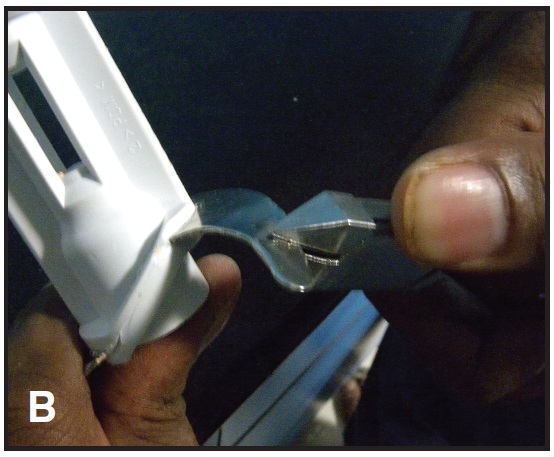

Because the appliance is intended for blending or chopping food ingredients such as nuts, meat, and onions, the blades are flat. For orthodontic use, we twist the blades obliquely with pliers so that the mixture will flow around the bowl and blend completely (B). These blades are sharp; great care must be taken while bending them and during operation and cleaning of the chopper.

Similar articles from the archive:

- TECHNIQUE CLINIC Mechanical Mixing of Glass Ionomer Cement November 1991

- Reducing Bond Failures with a No-Mix Adhesive February 1985

- Indirect Bonding with a No-Mix Adhesive June 1983

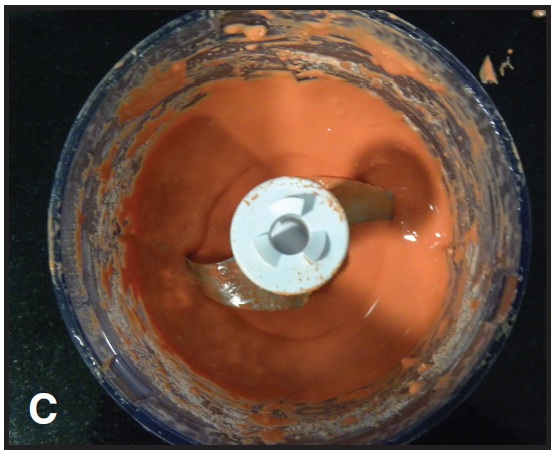

After alginate and water are added to the bowl according to the manufacturer's instructions, the blade unit is placed into the bowl and the shaft is fastened. When the switch is activated, a smooth and homogeneous mixture free of lumps or air bubbles will be formed within eight to 10 seconds (C). Clean-up is relatively easy.

We have experienced a nearly 30% reduction in mixing time with the food chopper compared to hand mixing. The appliance is inexpensive and widely available and has proved sturdy enough for regular use in our practices. It may also be an attractive alternative for practices that use intraoral scanners for most patient records, but occasionally need to take conventional impressions.

FOOTNOTES

- *Philips HR1351/C hand blender, Philips Electronics, Andover, MA; www.philips.com.