Soldered or welded TMA* and stainless steel wire hooks are used for postsurgical intermaxillary fixation and attachment of elastics. This article describes a quick and simple technique for welding single or multiple wire segments of either material.

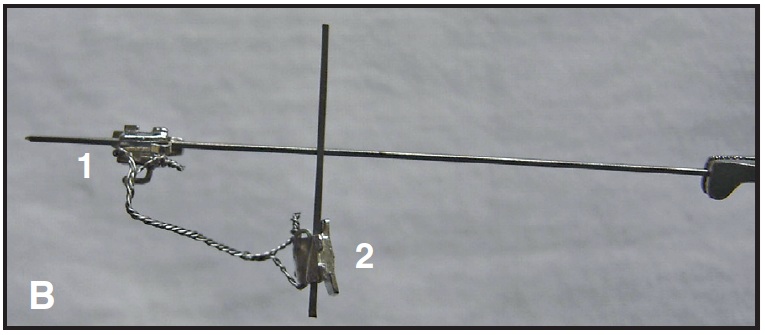

The Eezee Weld is made from two molar tubes, one with a slot size corresponding to the main archwire size (1) and one with a slot size corresponding to the size of the wire attachment to be welded (2). This will minimize any tendency of the archwire to rotate after the attachment is welded.

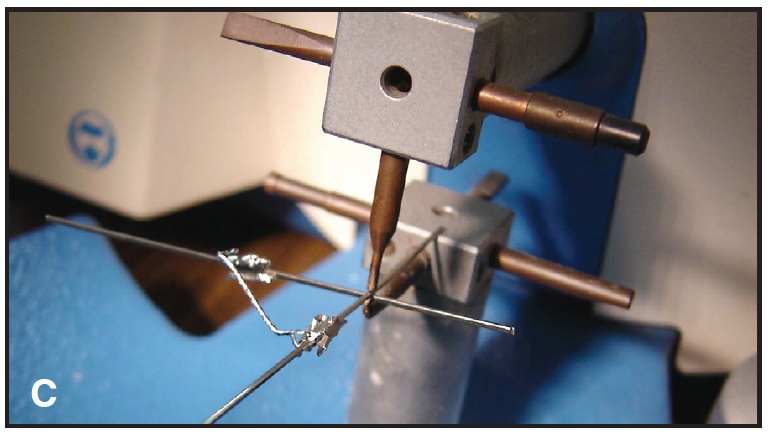

The molar tubes are connected through their auxiliary tubes with four strands of .010" stainless steel ligature wire, which are twisted together to ensure stability while allowing enough flexibility for minor adjustments (A). Molar tube 1 is slid along the main archwire until the wire attachment makes contact at the required angulation, often 90º (B). The wire attachment is then inserted into molar tube 2 to hold it in place for welding (C). Once welded, the wire attachment is cut above molar tube 2, and the remaining piece of wire is removed from the tube. Molar tube 1 can then be slid along the archwire for welding another attachment at a different site.

Similar articles from the archive:

The Eezee Weld can be removed without distorting the archwire, and can be reused for future welding if similar dimensions of wires are used.

FOOTNOTES

- *Registered trademark of Ormco/“A” Company, 1717 W. Collins Ave., Orange, CA 92867; www.ormco.com.