New Application of Superelastic NiTi Rectangular Wire

Nickel titanium (NiTi) alloy wires are now widely used in the medical field because of their unique shape memory effect and superelasticity. Since 1978, we have been conducting clinical studies on the superelastic property of NiTi round and rectangular orthodontic archwires and coil springs.

This article presents a new treatment method using NiTi rectangular wires.

Applications of Force Control

Rectangular wires have traditionally been reserved for the final stage of orthodontic treatment. The new superelastic NiTi rectangular wire (Neo Sentalloy) can be used with extremely light force in the initial phase of treatment. This means that three-dimensional tooth control (including root torquing) can be effected at the same time as horizontal and vertical leveling.

We previously reported on the heat-treatment method of force control with the superelastic NiTi wire. We found that the longer the heat treatment, the weaker the force became, but that heat treatment beyond a certain time produced negligible results.

Since then, we have found that many factors affect the force level of the superelastic NiTi wire, including the heat-treatment conditions, the processing method, and-- most important--the constituent ratio of the alloy. We have been able to lower the force level considerably by reducing the atomic ratio of the nickel.

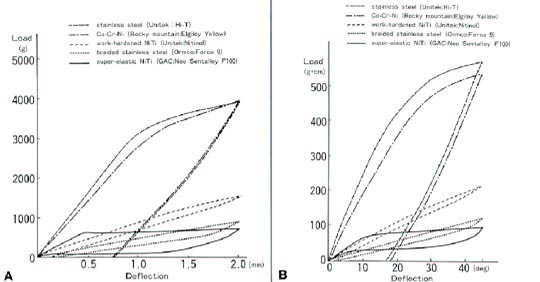

Figure 1 shows the results of a three-point bending test and a torque test on Neo Sentalloy F100 wire and other commercially available orthodontic wires. All the wires were .018" x .025" and were tested at 37°C. The load-deflection curve of this new NiTi alloy shows extremely light continuous force, regardless of deflection.

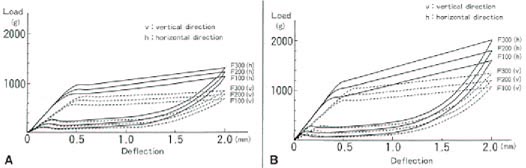

Figure 2 shows the results of the three-point bending test on NiTi wires of two different sizes ( .018" X .025" and .0215" X.028"), using superelastic forces of 100g (Neo Sentalloy F100), 200g (F200), and 300g (F300) for each size. The graphs demonstrate that superelastic force can be applied at a low level regardless of wire size. It is therefore possible to manage three-dimensional tooth movement, including torquing, from the early stages of orthodontic treatment.

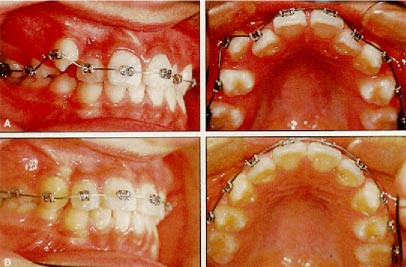

Figure 3 shows a case in which an .018" X .025" superelastic NiTi wire was used as the initial wire, with 100g of force. Five months later, leveling of the teeth, including torquing, had been achieved without any adjustments or archwire changes.

Use of Shape Memory Effect in Ideal Arch Formation

In heat treatment, the superelastic NiTi alloy not only changes its force level, but memorizes form. The latter characteristic makes it possible to condition an archwire so that it memorizes a particular archform, including torque, angulation, and buccolingual movements. The archwire can therefore be formed in the laboratory ahead of time, rather than using precious chairtime. The archform will also be more accurate than if it were bent at chairside.

We have developed the following technique for making individualized presurgical archforms using a setup model:

1. Bond the brackets directly to the teeth. Take a silicone impression of each arch. Make a separate set of the same brackets, and solder a wire attachment to each bracket base to keep the bracket from shifting (Fig. 4). Place the new brackets in the silicone impression (Fig. 5), and pour plaster casts.

2. Mount the casts on an articulator (Fig. 6), and align the teeth in their postsurgical positions (Fig. 7).

3. Ligate the superelastic NiTi wires to the working casts (Fig. 8).

4. Cover each working cast with the same plaster used to make the casts, and heat-treat it in an electric furnace (Fig. 9). Confirm the heat-treatment temperature with a chromel-alumel thermocouple. Treating at 510°C for three to five minutes provides the proper conditions for the archwire to accurately memorize the ideal archform (Fig. 10).

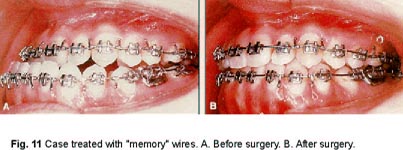

Figure 11 shows a surgical-orthodontic case treated with this method.

Discussion

The superelastic NiTi rectangular wire makes it possible to exert three-dimensional control throughout treatment. Tooth control can be even more accurate as the wire size is increased, but bracket friction then becomes more of a problem. The use of larger wires is currently being studied.

These NiTi wires are used mainly with preadjusted brackets, but the concept of shape memory is the opposite of preadjusted appliances such as the Straight-Wire Appliance. By using shape memory and a setup model, we can not only use standard brackets; theoretically, we can move the teeth to the positions of the setup model even if bracket positioning is difficult because of crowding or occlusion.

In addition, with "reversible control" of the force level, the same wire used with continuous light forces in the initial phase can be used throughout treatment by gradually increasing the force level. Using a single, "memory-treated" wire eliminates the need to change archwires periodically. It makes orthodontic treatment more accurate and also saves chairtime and the clinician's energy.

We have found the memory treatment effective in surgical-orthodontic cases. However, there are problems to be resolved in extraction cases and in controlling arch width. These require further study and clinical trials.